State-of-the-art packaging solution

State-of-the-art packaging solution for bricks and building materials

If exceptional load stability, toughness and weather protection and cost benefits are critical for your business, then NexxstarTM resin formulations for stretch hood packaging films are your load protection solution.

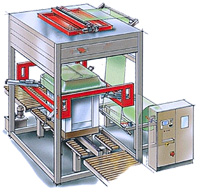

Created by ExxonMobil Chemical, Nexxstar resin formulations form the basis of innovative coextrusion films. Coupled with state-of-the-art stretch hood equipment, it offers considerable, added-value benefits for the brick and building materials industries.

Cost benefits, higher holding forces, superb puncture resistance and no tear propagation — even at elevated temperatures — make Nexxstar resin formulated solutions the perfect film for pallet transportation and storage of bricks and building materials. In addition, a Nexxstar formulated film is so transparent it provides builders and retail-store customers with a clear view of the packed material.

An Outstanding Range Of Benefits

Outperforming stretch wrapping, shrink hood and existing stretch hood films, the Nexxstar stretch hood solution can offer the following benefits :

If exceptional load stability, toughness and weather protection and cost benefits are critical for your business, then NexxstarTM resin formulations for stretch hood packaging films are your load protection solution.

Created by ExxonMobil Chemical, Nexxstar resin formulations form the basis of innovative coextrusion films. Coupled with state-of-the-art stretch hood equipment, it offers considerable, added-value benefits for the brick and building materials industries.

Cost benefits, higher holding forces, superb puncture resistance and no tear propagation — even at elevated temperatures — make Nexxstar resin formulated solutions the perfect film for pallet transportation and storage of bricks and building materials. In addition, a Nexxstar formulated film is so transparent it provides builders and retail-store customers with a clear view of the packed material.

An Outstanding Range Of Benefits

Outperforming stretch wrapping, shrink hood and existing stretch hood films, the Nexxstar stretch hood solution can offer the following benefits :

- 40% or more cost reduction when compared to shrink hood packaging (through down-gauging, lower film consumption) .

- Outstanding toughness and higher holding force even at elevated temperatures .

- Excellent load stability for a myriad of load types and pallet sizes .

- Flexible (automatic) adaptation to load height, width and depth .

- Superb clarity for optimum material visibility, quality control and retail display

- Excellent tear and puncture resistance.

- Exceptional weather protection with optional five-side packing (rain, dirt and dust-proof).

- Visually smooth finish with no loose or flapping ends.

A BETTER ALTERNATIVE

Compared to typical end-of-line packaging solutions, films using Nexxstar resin formulations represent major advances in performance.

Compared to typical end-of-line packaging solutions, films using Nexxstar resin formulations represent major advances in performance.

Advantages over shrink packaging can include :

- Up to 40% cost reduction due to film down-gauging and lower film consumption per pallet.

- Reduced energy consumption as no shrinking is required.

- Outstanding load stability as Nexxstar resin formulations for stretch hood films provide improved horizontal and vertical holding forces , even at elevated temperatures.

- Nexxstar formulated films do not lose elasticity and easily adapt to shape changes due to load setting.

- Higher packaging speeds compared with single-stage shrink hood machines.

Advantages over stretch wrap can include :

- Better product protection against rain, dust and dirt, thus providing greater flexibility in handling and outdoor storage.

- Outstanding load stability as Nexxstar resin formulations for stretch hood films provide horizontal and vertical holding forces, even atelevated temperatures .

- Up to two-fold higher packaging speeds .

- Improved product presentation due to exceptional optical properties .

- Tamper evident packaging .